Bigge Power Constructors has built large capacity derrick cranes intended for large scale modular construction of nuclear power plants. Each crane rolls on a circular track. This particular application required a capacity of 4,000 short tons at a radius of 240 feet from the center of rotation, 836 short tons at 640 feet, and 500 short tons at 790 feet.

Category: Heavy Lift & Rigging Projects

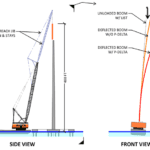

McLean High-Reach Floating Crane Feasibility Study

McLean Contracting Company needed a high-reach floating crane to install offshore power line supports in Baltimore. The highest lift was 400 feet above water. Liftech evaluated the feasibility of retrofitting their 400T Baltimore floating crane with a long jib to perform the lifts. Liftech developed the design criteria, assisted with developing a conceptual jib erection scheme, reviewed crane system strength…

1,700 t Floating Crane Design Review “Left Coast Lifter”

Liftech provided design assistance and review services to American Bridge/Fluor Enterprises (ABF) for procurement of a shear leg derrick. The derrick is used to erect the major components of the San Francisco-Oakland Bay Bridge self-anchored suspension span. The crane with a 100-m boom has 1,700 t capacity at 60 degrees. The crane has two auxiliary hooks with capacities of 100 t and 10 t. The boom is configured to lay down for transport within the USA river system.

Manzanillo International Terminal Crane Raises, Republic of Panama

Manzanillo International Terminal (MIT) hired Global Rigging and Transport (GRT) to increase the lift height of eight ZPMC ship-to-shore (STS) cranes located in Panama, and potentially for other terminals in Mexico and Chile. Liftech provided design review for structural modifications to increase the lift height of two STS crane designs. Earlier, Liftech assisted MIT with the initial procurement of these…

AmClyde Floating Cranes

AmClyde supplied two semi-submersible vessels with twin revolving derricks of 6,000 t and 7,000 t capacity each. Liftech was part of the AmHoist design team and assisted in designing the crane booms. Reference: AmHoist St. Paul, Minnesota, USA

Staples Center Roof Erection

Staples Center, completed in 1999, is the home of the LA Lakers, Clippers, and Kings. Bickerton Iron Works was the rigging contractor selected to assemble, erect, and rig the roof structure. Liftech was retained by Bickerton as the structural engineer.

8,000 t Floating Crane Design Review

ZPMC supplied an 8,000 t double boom shear leg floating crane to Samsung Heavy Industries Company Limited. The crane has 8 main hooks, each with a 1,000 t capacity. The crane is rated for 8,000 t at 82 m from boom heel. Liftech assisted ZPMC with developing the overall concept and layout, and designing various crane structural components.

Jacking Frame for Raising Container Cranes

The existing jacking equipment for raising container cranes required a long time to set up and disassemble. Some equipment imposed unacceptable loads on the dock. Liftech designed a jacking frame that enables BIW to raise cranes in less than a week. The frame is capable of raising cranes 30 feet, can withstand up to 75 mph winds with the crane raised, and is supported on crane sill beams.

SSA Mexico Paceco Crane Gage Change and Relocation

SSA Mexico relocated a 50’ gage Paceco crane from the Port of Long Beach, California, to Manzanillo, Mexico. The crane was built around 1980 and was raised in the late 1980s. Liftech provided engineering to change the gage from 50’ to 55’ and for the associated rigging work. The frame was strengthened for higher wind loads, and new stowage brackets and tie-downs were added.

Hitachi Crane Modification and Relocation

Horizon Lines and Matson Navigation purchased three Hitachi cranes located in Los Angeles, California, for relocation to Guam. The cranes were upgraded and strengthened for typhoon winds. Upgrades included a lift height increase of 8 feet, new drives and controls, diesel power, and new tie-downs.