At the Middle Harbor Terminal, a problem existed with the wharf batter piles. Some batter piles would intrude into the ship berth if the berth were to be dredged to a deeper depth. Liftech prepared a study to determine which piles should be replaced and then designed the installation of the replacement piles.

Category: Wharf Projects

Port Everglades Berth 30 Crane Transfer System Design

Many wharves have nonlinear berths that meet at a corner. It is often economical to share cranes between these berths. To share, cranes must transfer between them. Transfer methods range from shuttle systems that move the cranes between the berths to curved rails that the cranes gantry on. Recently, the most popular method has been the curved rail.

Guam Post-Earthquake Wharf Evaluation and Design of Reconstruction of Damaged Wharf

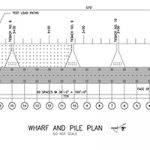

The original 1900-foot-long wharf consisted of a waterside sheet pile bulkhead tied back to sheet pile deadmen and an independent crane runway supported on steel H piles. The 1993 earthquake induced soil liquefaction, settlement, and lateral spreading. The entire length of wharf and crane runway rotated and translated with significant damage to about 560 feet of the middle portion.

VPA PMT Wharf Evaluation and Modification

The rated capacity of existing wharf structures was increased up to 35% after Liftech evaluated the strength of the structures at Portsmouth Marine Terminal. Increasing the rated load eliminated the need to strengthen the wharves or limit the operations of the larger, newly purchased cranes. Liftech’s assessment included state-of-the-art methods such as strut and tie.

Port of New Orleans Wharf Analysis

Global Rigging & Transport unloaded two Doosan cranes at the Port of New Orleans using a dolly system. Liftech reviewed the wharf structure to determine its adequacy to support the dolly loads and helped select the offload location. Reference: Global Rigging & Transport, LLC Virginia Beach, Virginia, USA

Virginia Port Authority, Stowage Hardware Design

VPA needed cranes for their Portsmouth Marine Terminal facilities. They purchased three new ZPMC cranes, knowing the PMT wharf had wheel load and other limitations. On the crane side, VPA retained Liftech to work with ZPMC to assist in designing a light-weight truss boom crane for reduced waterside wheel loads. On the wharf side, Liftech reviewed the wharf girders and designed new stowage hardware.

Justify Higher Wharf Capacity by Load Test, Port of Oakland

The Port of Oakland retained Liftech and Geomatrix to determine the crane girder capacity at all wharves at the port. Based on Geomatrix’s analysis, the piles at Berths 24 and 25 did not have adequate capacity for the current cranes. Liftech designed a load test that confirmed the piles were strong enough to carry the crane loads. An analysis of the test data was used to increase the calculated capacity at other wharves at the port.

Justify Higher Wharf Capacity by Load Test, Port of Richmond

The Port of Richmond wanted to know if their 60-plus year old wharf at Pt. Potrero Terminal could service break-bulk cargoes and support 40,000 lb double axle wheel loads. At Berth 7, the wharf surface and some of the wood piles had deteriorated from lack of maintenance. Conventional analysis could not justify supporting the desired wheel loads.