Liftech provided engineering to demolish the articulated boom Crane X437 at Port of Oakland Berth 37, including review of the associated wharf loads Power Engineering Construction Co. used their DB Pacific floating crane, a Liebherr LR1300 crawler crane, and a hydraulic mobile crane. The crawler and mobile cranes imposed large, localized loads on the wharf structure. Liftech’s scope included wharf review…

Category: Wharf Projects

Crane Procurement, Crane Modification, and Wharf Expansion, Port Everglades Department of Broward County, Fort Lauderdale, Florida

Port Everglades operates seven 1990s, 46.5-LT capacity low profile STS cranes at their Southport terminal for servicing vessels up to 16 containers across. The port is also serving vessels up to 22 containers across with up to 8 high on deck and purchased new 65-LT capacity cranes. Liftech made studies to determine parameters for the new cranes and identify required upgrades to…

Port of Oakland Berths 57-59 Wharf Design

Liftech designed a new 3,600-foot container wharf for the Port of Oakland at Berths 57-59. This $90 million construction project gives the port a state-of-the-art facility designed to resist the highest probable earthquakes with minimum damage. The wharf serves six new container cranes for which Liftech provided design and fabrication review.

Cemex West Sacramento Wharf Project

Liftech worked with Manson Construction as part of their design-build team to design the wharf, access bridge, and mooring platform structures for a cement unloading facility for Cemex Inc. The 550-foot wharf supports a cement unloader and screw conveyor system to transfer cement from the vessel to storage structures on land. The moment frame design for the wharf structure limits seismic forces on the unloader and conveyor structures.

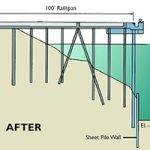

Port of Oakland Berths 32/33 Rehabilitation

Liftech designed a remodel to a 1,500-foot container wharf for the Port of Oakland at Berths 32/33 and a new 250-foot wharf extension to Berth 30. This $20 million construction project allows 100-foot rail span container cranes to travel from the Berth 30 wharf to the Berths 32/33 wharf. In addition, sheet piling was installed at the toe of the embankment to allow the berth to be dredged to elevation -55 feet. Without the remodel, Berths 32/33 could only accommodate 34-foot rail span cranes, and the cranes could not travel between Berths 32/33 and Berth 30.

Port of Redwood City Wharf Design

Liftech worked with Manson Construction Company as part of their design-build team to design a 426-foot-long wharf, two access bridges, a 955-foot-long sheet pile seawall, mooring platforms, walkways, and a longshoreman building. The moment frame and thin deck of the wharf structure limit the seismic forces and number of piles required.

IMTT, Marine Oil Terminal, Wharf Replacement

International-Matex Tank Terminals (IMTT) replaced portions of an existing wood wharf structure at their Richmond, California, facility to meet Marine Oil Terminal Engineering and Maintenance Standards (MOTEMS). Liftech worked with Manson Construction Company to develop the replacement design.

Halifax Port Authority, Wharf Crane Girder Capacity Study

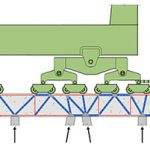

A Halifax Port Authority tenant purchased new ship-to-shore container cranes. The wharf was extended several times between 1969 and 2010. The new crane wheel loads exceeded the allowable wheel loads on the existing girders. The port authority was faced with the possibility of reinforcing the majority of the girders. Liftech analyzed the girders and estimated the girder capacity for shear, flexure, concrete bearing, and pile bearing.

McNears Beach Pier Repair and Seismic Upgrade

During a storm, a 100’ by 400’ barge broke its mooring and collided with the pier at McNears Beach Park, damaging about half of the pier structure. The original pier structure consisted of a precast concrete superstructure supported by slightly battered 18” octagonal precast, prestressed piles. Liftech designed a replacement pier structure with details to provide significantly better seismic performance.

Port of Oakland Wharf and Crane Study

Liftech conducted an extensive wharf and crane study to help the Port of Oakland in their overall planning. Liftech calculated the ultimate wheel load capacity of all crane rail girders, waterside and landside, at all dockside container wharves for current and future channel depths. Liftech also calculated the wheel loads of all the dockside container cranes at the port. The port can use the calculated capacities to determine which cranes can be relocated from one wharf to another.