Liftech conceived a new crane concept, the Balance Crane, for unloading containers from large vessels and developed the design in collaboration with crane manufacturer ZPMC, Shanghai, China. The Balance Crane has reduced wheel loads and tie-down loads compared to a standard ship-to-shore container crane but functions similarly. The boom is continuous from the landside legs to the boom tip. The…

Category: Crane Design Projects

Port Everglades Low Profile Crane Procurement, Fort Lauderdale, Florida

Port Everglades (PED) serves vessels up to 22 containers across and 8 high on deck at their Southport terminal with three new 65-LT capacity low profile STS cranes procured from ZPMC China with help from the Liftech team, also including McKay International Engineers, Leader Firm International, and Liftech Shanghai Limited. At the time of construction, these were the three largest low…

Bigge Heavy Lift Cranes

Bigge Power Constructors has built large capacity derrick cranes intended for large scale modular construction of nuclear power plants. Each crane rolls on a circular track. This particular application required a capacity of 4,000 short tons at a radius of 240 feet from the center of rotation, 836 short tons at 640 feet, and 500 short tons at 790 feet.

Truss Boom Crane Design

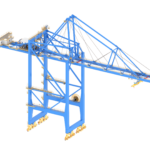

The client operates terminals at a port in southern China and wanted to procure five new super post-Panamax cranes for a terminal with limited wheel load and tie-down load capacity. ZPMC proposed a truss boom and girder design to reduce wheel loads and tie-down loads. Liftech assisted the client by participating in the conceptualization and design of the upper works structure…

Sydney Low Profile Crane Procurement

Liftech assisted Sydney International Container Terminals Pty Ltd with structural design and review of four post-Panamax ZPMC low profile shuttle boom cranes for their new container terminal across from an airport in Sydney, Australia.

FastNet

Liftech participated with APM Terminals to conceptualize and design FastNet, a crane technology that enables STS gantry cranes to work adjacent, instead of alternate, bays of a large container ship. APMT estimates that FastNet can deliver berth productivity of 450 moves an hour.

8,000 t Floating Crane Design Review

ZPMC supplied an 8,000 t double boom shear leg floating crane to Samsung Heavy Industries Company Limited. The crane has 8 main hooks, each with a 1,000 t capacity. The crane is rated for 8,000 t at 82 m from boom heel. Liftech assisted ZPMC with developing the overall concept and layout, and designing various crane structural components.

Port of Singapore Machinery-on-Trolley Crane Design

Liftech worked closely with MHI engineers to optimize the crane weight and structural performance of both the main crane structure and the trolley. The resulting structural design meets all of PSA’s stringent deflection requirements. The boom features a trapezoidal monogirder design with a single forestay.

AmClyde Floating Cranes

AmClyde supplied two semi-submersible vessels with twin revolving derricks of 6,000 t and 7,000 t capacity each. Liftech was part of the AmHoist design team and assisted in designing the crane booms. Reference: AmHoist St. Paul, Minnesota, USA

1,700 t Floating Crane Design Review “Left Coast Lifter”

Liftech provided design assistance and review services to American Bridge/Fluor Enterprises (ABF) for procurement of a shear leg derrick. The derrick is used to erect the major components of the San Francisco-Oakland Bay Bridge self-anchored suspension span. The crane with a 100-m boom has 1,700 t capacity at 60 degrees. The crane has two auxiliary hooks with capacities of 100 t and 10 t. The boom is configured to lay down for transport within the USA river system.